Customers Problem:

A customer had a problem with catalytic beads within a double skinned, water-cooled reactant column. Everything worked well at low flow rates, but as end-users demanded ever higher flow rates, the catalytic beads were breaking apart, being carried downstream and interfering with equipment.

HDL’s Solution:

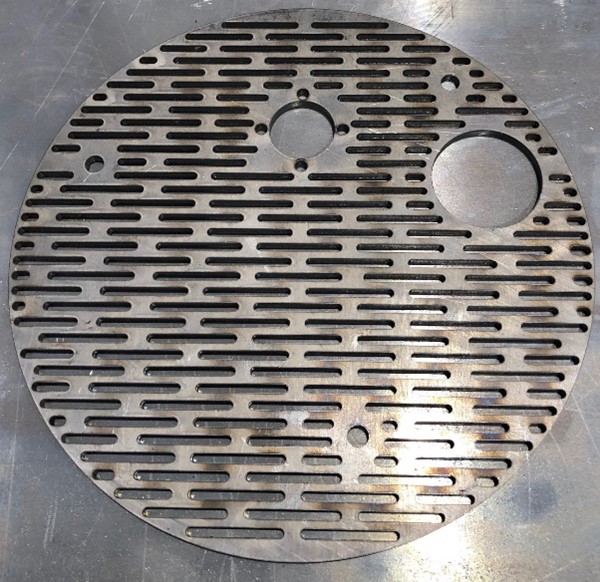

After examination of the reactant tube, HDL determined that the beads were not adequately compacted and were becoming fluidised under the high flow rates. HDL recommended a new filling method and designed sprung plates to sit at either end of the column to distribute the flow of gas evenly across the diameter of the tube and to ensure that even if further settling occurs, the reactant beads will remain compacted and will not become fluidised. These plates were known as the Death Star, for obvious reasons!